Parker designed its BHA industrial dust collection bags, baghouse filters, pleated cartridge filters, and dust collector replacement parts to decrease maintenance time and labor costs while adding value to our customers' filtration systems.

With today's demands of increased production and tighter emission controls, dust collectors can be pushed beyond their design limits. If they fail to keep up, production and profitability suffer. As an alternative to traditional filtration technology, Parker offers an innovative and extensive range of pleated, cartridge, and membrane bag filters, as well as related bags, cages, parts, and accessories for proven performance and durability.

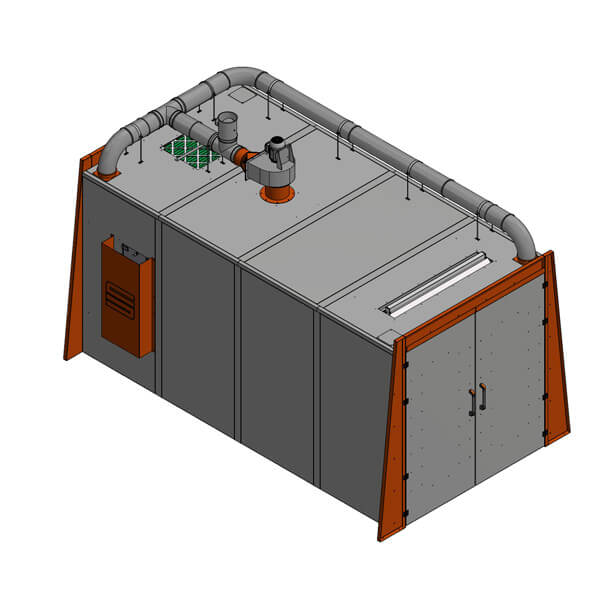

When timelines are short and expectations high, it's great to have an experienced, responsive partner. We make sure we help you select the right product for the right application, including powder coating, abrasive blast, weld and plasma smoke, and other industrial processes. Filter media selection is one of the most critical factors in optimizing fabric filter performance. It's our goal to continually improve our processes and our products so that we can address your needs with high-performing, cost-effective solutions.

OEM Dust Collector Cartridge Filters

We make cartridge filters for many of the OEM’s: Donaldson AAF, Airflow Systems, Donaldson Torit, Camfil Farr APC, FlexKleen, ITW/Gema, Nordson, Micro Air, Pnuemafil, UniWash/Polaris, Robovent, Sly, Steelcraft, Wheelabrator, GFS (Global Finishing Solutions), Micro Air, and more.*